Product Center

-

Multi Parameter Water Quality Analyzer

-

COD/BOD Analyzer

-

Determination of Ammonia Nitrogen

-

Determination of Total Phosphorus and Total Nitrogen

-

Biological Toxicity Testing

-

Disinfection Residue Determination

-

Online water quality monitoring instrument

Dissolved oxygen online analyzer PH online monitoring device Chloride ion online monitoring instrument Conductivity online monitoring device Turbidity online monitoring instrument Online water hardness monitoring instrument ORP online monitoring device Residual chlorine online monitoring device Total organic carbon monitoring equipment -

Other related tests

Water quality heavy metal detector Infrared oil analyzer Water quality nitrite analyzer Colorimeter Dissolved oxygen analyzer Turbidity detector Total OrganicCarbon Analyzer Chlorophyll detector in water Suspended solids analyzer Water quality total hardness/total alkalinity detector Surfactant detector Proportional water quality sampler Microbial detector in water Sulfide acidification blowing instrument Carbon dioxide detector in water Online water quality sensor Volatile Phenol Analyzer Phosphate Silicate Analyzer

Recommended articles

- Hengmei Intelligent Infrared Spectrophotometric Oil Analyzer Product Knowledge Graph White Paper

- Portable Total Phosphorus Detector Product Knowledge Graph White Paper

- Infrared spectrophotometer: the "spectral guardian" guarding green mountains and clear waters

- Product Knowledge Graph White Paper for Hengmei Intelligent Water Bromate Tester (Model: HM-TBr)

- Biological toxicity detector based on bioluminescence sensing technology: principles, advantages and applications

- Water Quality Detector | Portable Multi-Parameter Analyzer

Current

location:HOME>PRODUCT>Other related tests>Online water quality sensor>Water Quality Conductivity Sensor

Current

location:HOME>PRODUCT>Other related tests>Online water quality sensor>Water Quality Conductivity Sensor

Product details

Application Environment Description

Used for environmental water quality testing and various high/low ion strength water sample testing, it can meet the requirements of most industrial/environmental applications for online conductivity measurement.

Signal output: RS485 (MODBUS-RTU).

Internal signal isolation technology has strong interference.

Good reproducibility, thermal stability, low drift, small size, fast response speed

Easy to install, simple, 3/4NPT pipe thread, easy to sink or install in pipelines and tanks

Stable performance and long service life

IP68 waterproof standard

24*1.2 18*1.5*2 28*2 2

Technical performance and specifications

1. Technical parameters

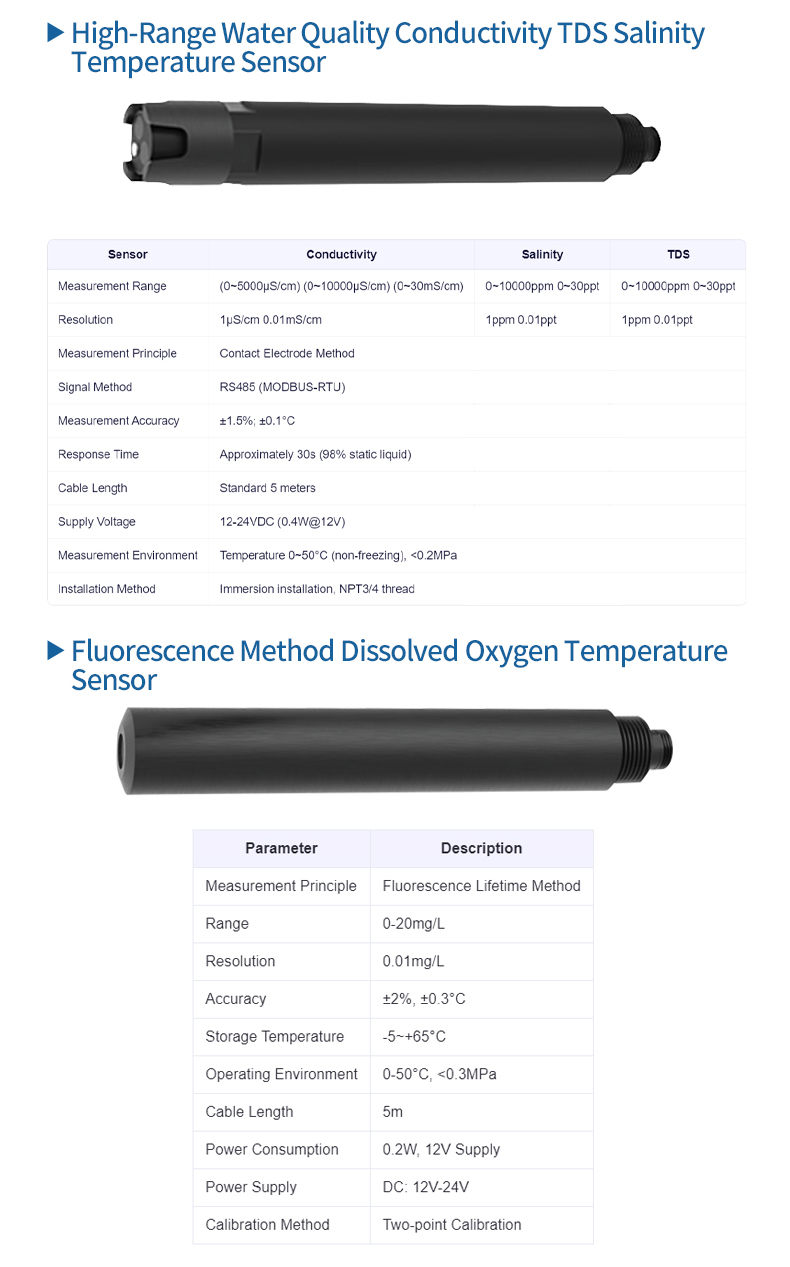

Measurement principle: Contact electrode method

Signal mode: RS485 (MODBUS-RTU)

Measurement range: 0~10000uS/cm

Measurement resolution: 1

Measurement accuracy: ± 1.5%; ±0.1 °C

Response time: approximately 30 seconds (98% static liquid)

Shell material: ABS and 316L stainless steel

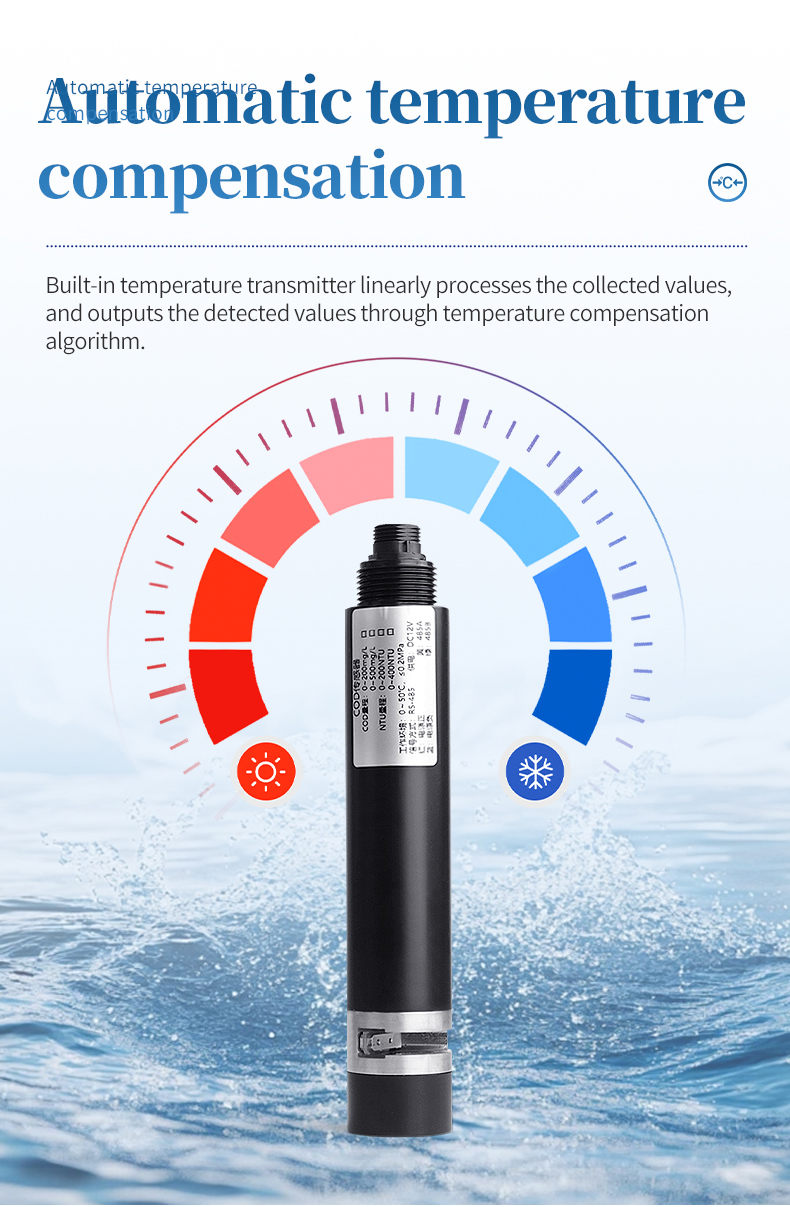

Temperature compensation: Automatic temperature compensation (M1820Z)

Cable length: standard 5 meters

Supply voltage: 12-24VDC( 0.4W@12V )

Measurement environment: temperature 0~50 ℃ (non freezing),<0.2MPa

Waterproof rating: IP68

Installation method: Immersion installation, NPT3/4 thread

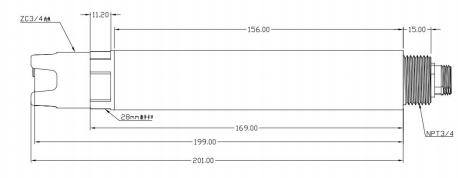

2. Dimensional drawing

The sensor connector is an M12 aviation plug connector with a 5-pin female socket

Installation and electrical connections

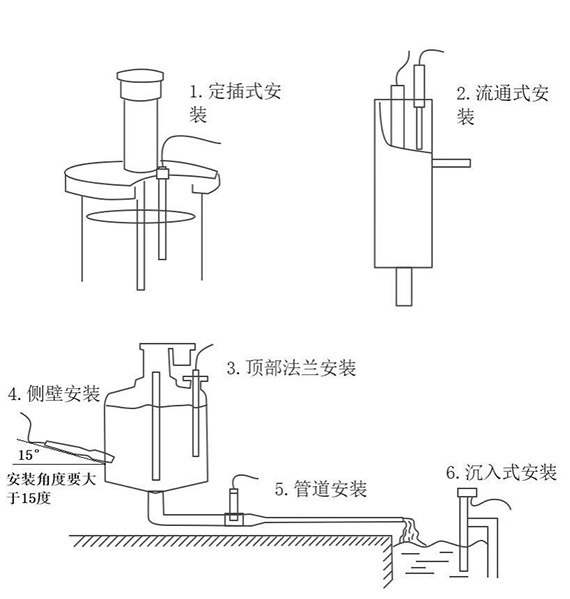

1. Installation

Attention: The sensor should not be installed upside down or horizontally, and should be installed at an angle of at least 15 degrees.

2. Electrical installation

The cable is a 5-core shielded wire, and the line sequence is defined as brown - power line (12~24VDC)

Black Ground (GND)

Blue -485A Green -485B

Yellow -4-20mA current output (can be suspended if not in use)

Before powering on, carefully check the wiring sequence to avoid unnecessary losses caused by wiring errors.

Maintenance and upkeep

1. Use and maintenance

Conventional electrodes require periodic cleaning and calibration, and maintenance intervals are determined by customers based on their own operating conditions. The cleaning method for conventional electrodes: Use a soft bristled brush to remove attachments (be careful not to scratch the electrode surface), then clean with distilled water, and then perform calibration operation.

Article address:http://www.hmwatertesting.cn/qtjc16/131.html

Related articles

-

COD, Ammonia Nitrogen, Total Phosphorus and Total Nitrogen Detector Product Knowledge Graph White Paper

2025-12-03 -

BOD Analyzer | Effluent and Environmental Testing

2025-10-22 -

Water Quality Ozone Detector: Rapid and Accurate On-Site Ozone Monitoring Solution

2025-09-19 -

Chlorine dioxide detectors measure the concentration of chlorine dioxide in drinking water

2025-07-23 -

Multi-Parameter Water Heavy Metal Detector: Spectrophotometry-Based Detection for 10+ Metals

2025-10-30 -

Infrared spectrophotometer: the "spectral guardian" guarding green mountains and clear waters

2025-07-15 -

Handheld residual chlorine analyzer: a portable guardian of water quality safety

2025-07-15 -

What is the best water tester for drinking water?

2025-07-23

+86 17853698681

+86 17853698681