Product Center

-

Multi Parameter Water Quality Analyzer

-

COD/BOD Analyzer

-

Determination of Ammonia Nitrogen

-

Determination of Total Phosphorus and Total Nitrogen

-

Biological Toxicity Testing

-

Disinfection Residue Determination

-

Online water quality monitoring instrument

Dissolved oxygen online analyzer PH online monitoring device Chloride ion online monitoring instrument Conductivity online monitoring device Turbidity online monitoring instrument Online water hardness monitoring instrument ORP online monitoring device Residual chlorine online monitoring device Total organic carbon monitoring equipment -

Other related tests

Water quality heavy metal detector Infrared oil analyzer Water quality nitrite analyzer Colorimeter Dissolved oxygen analyzer Turbidity detector Total OrganicCarbon Analyzer Chlorophyll detector in water Suspended solids analyzer Water quality total hardness/total alkalinity detector Surfactant detector Proportional water quality sampler Microbial detector in water Sulfide acidification blowing instrument Carbon dioxide detector in water Online water quality sensor Volatile Phenol Analyzer Phosphate Silicate Analyzer

Recommended articles

- What instrument is used to measure TOC?

- Portable Infrared Spectrophotometer for Oil Analysis: Rapid On-Site Detection of Water and Soil Oil Pollution

- Bromate Rapid Detector: Essential for Ensuring Packaged Drinking Water Safety

- Portable Total Phosphorus Detector Product Knowledge Graph White Paper

- What are the water quality tester test items?

- BOD Analyzer | Effluent and Environmental Testing

Current

location:HOME>PRODUCT>Other related tests>Online water quality sensor>Fluorescence Based Dissolved Oxygen Sensor

Current

location:HOME>PRODUCT>Other related tests>Online water quality sensor>Fluorescence Based Dissolved Oxygen Sensor

Product details

Working principle

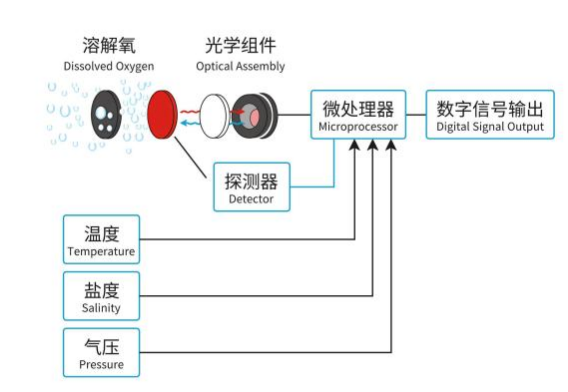

The fluorescence based dissolved oxygen sensor is designed based on the quenching principle of excitation fluorescence by specific substances in physics. When the excitation light is irradiated onto the fluorescent substance on the surface of the fluorescent film head, the fluorescent substance is excited and emits fluorescence. The extinguishing time of the fluorescence is affected by the concentration of oxygen molecules on the surface of the fluorescent film head. The concentration of oxygen molecules can be calculated by detecting the luminescence lifetime of fluorescence, and the final value can be output after temperature, pressure, and salinity compensation.

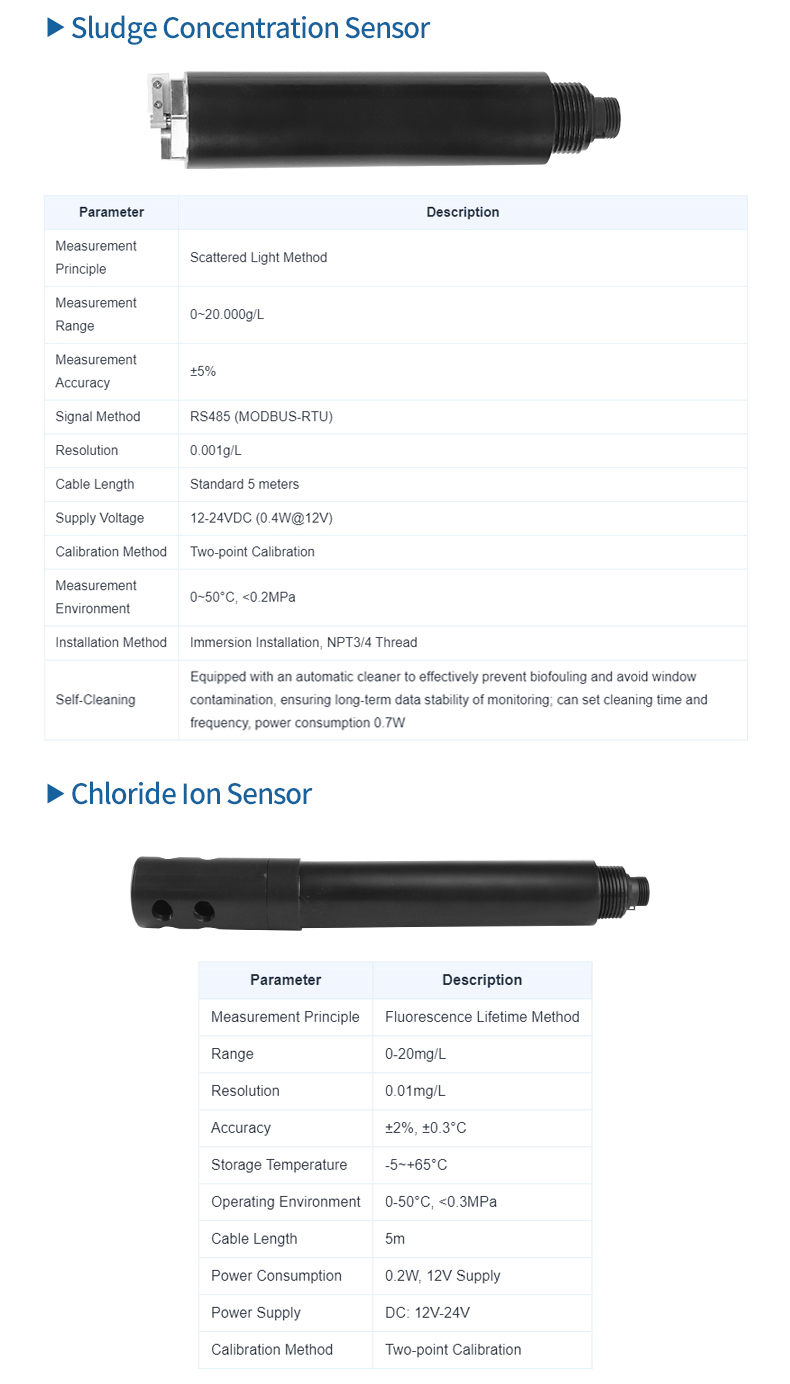

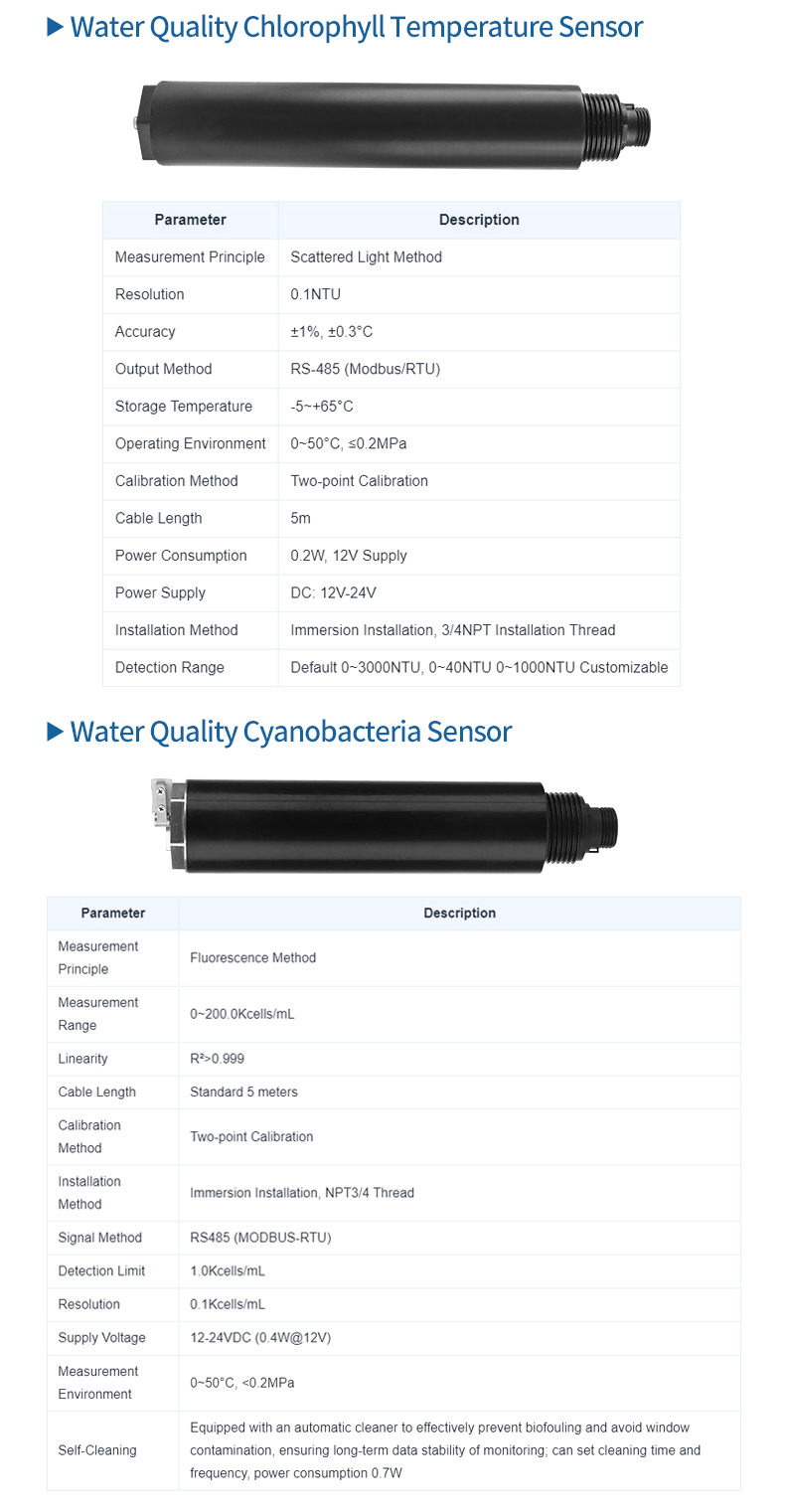

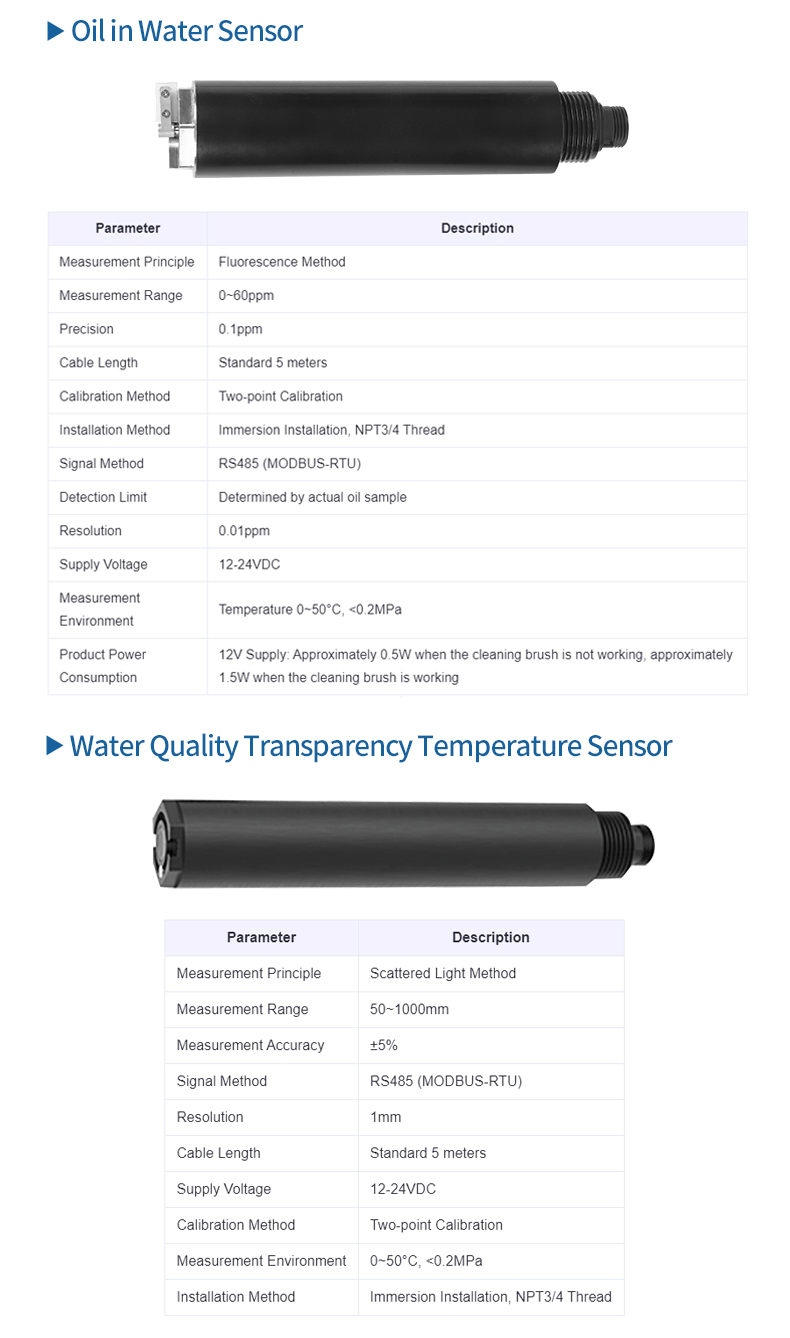

Technical Specifications

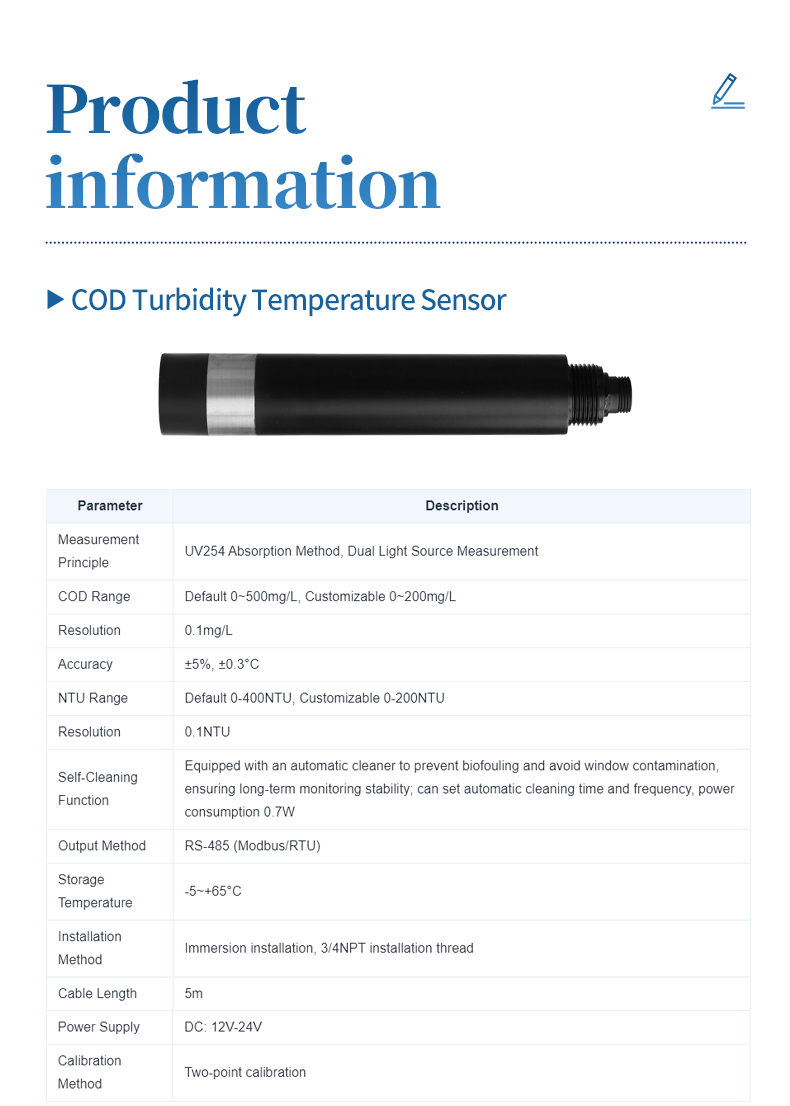

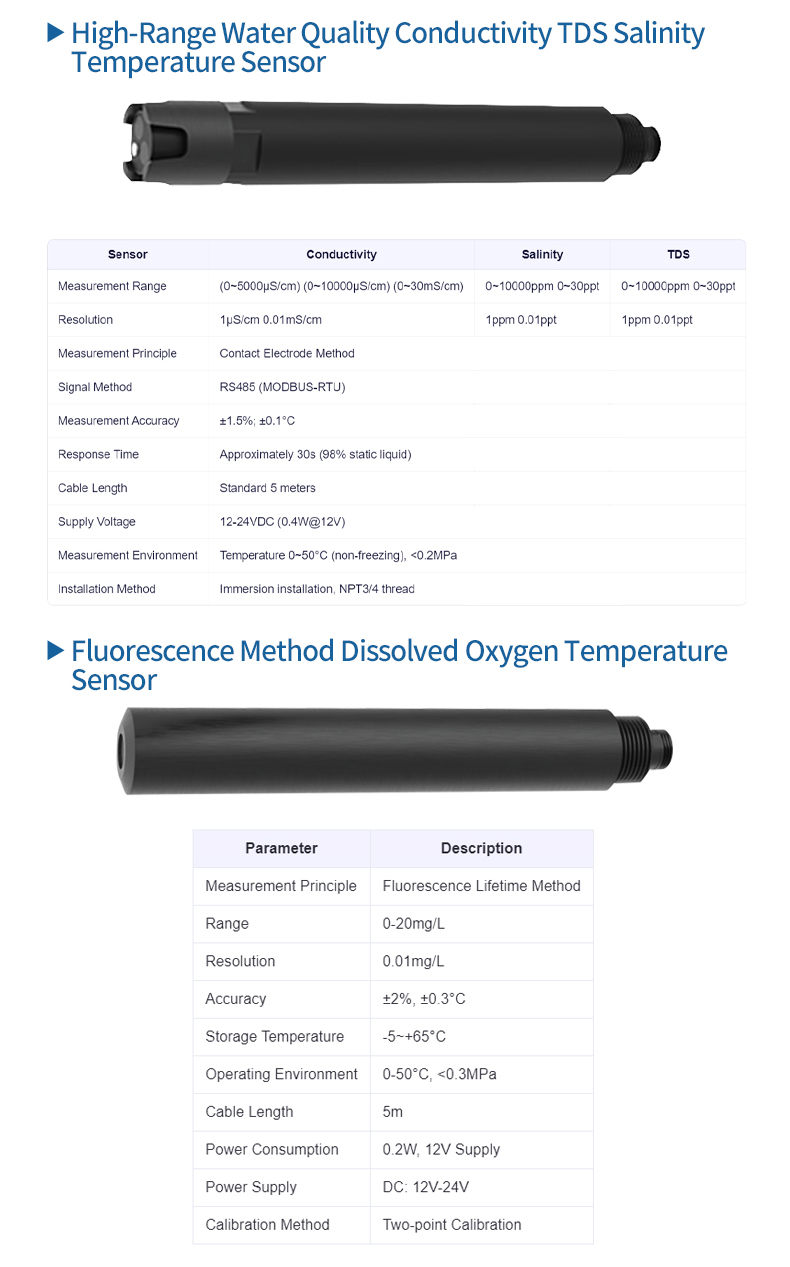

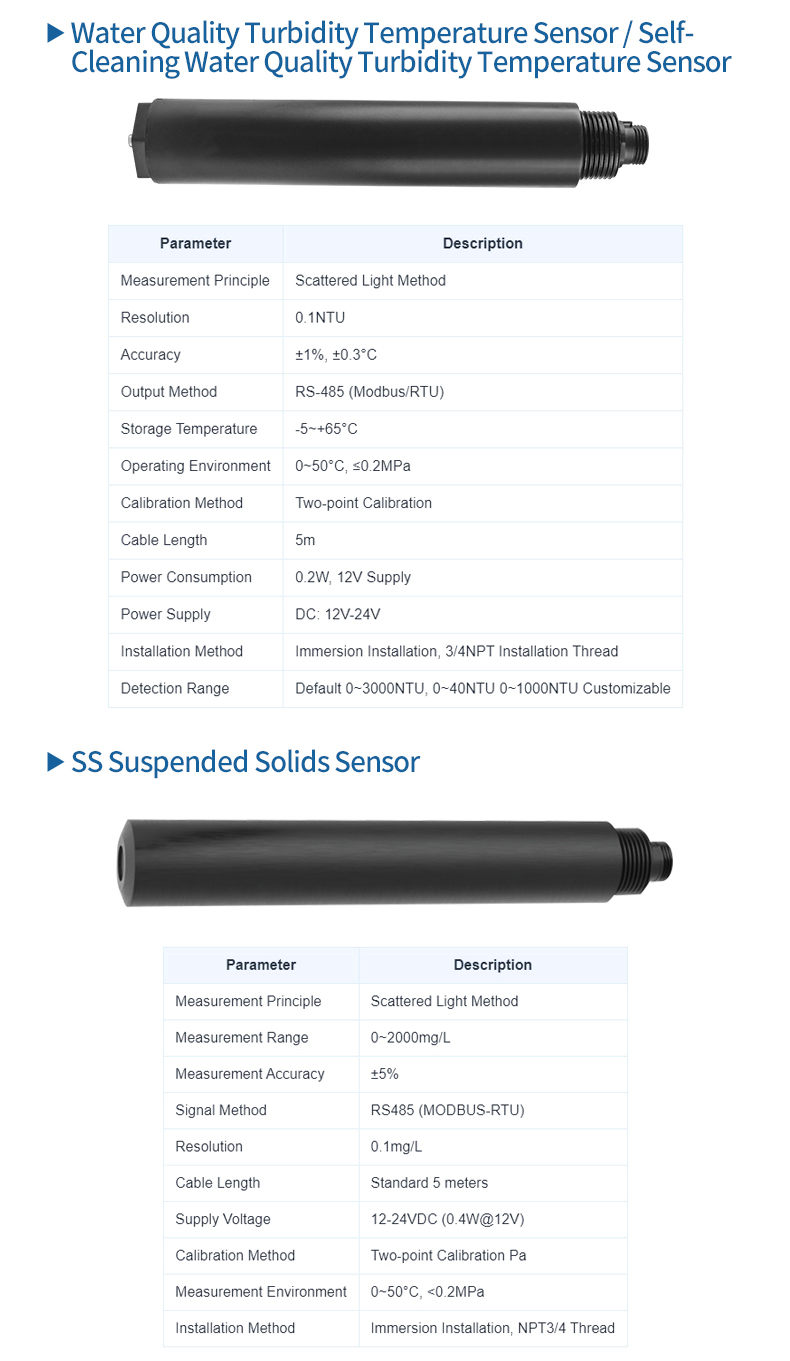

Measurement principle: Fluorescence lifetime method

Range: 0-20mg/L

Resolution: 0.01mg/L

Accuracy: ± 2%, ± 0.3 ℃

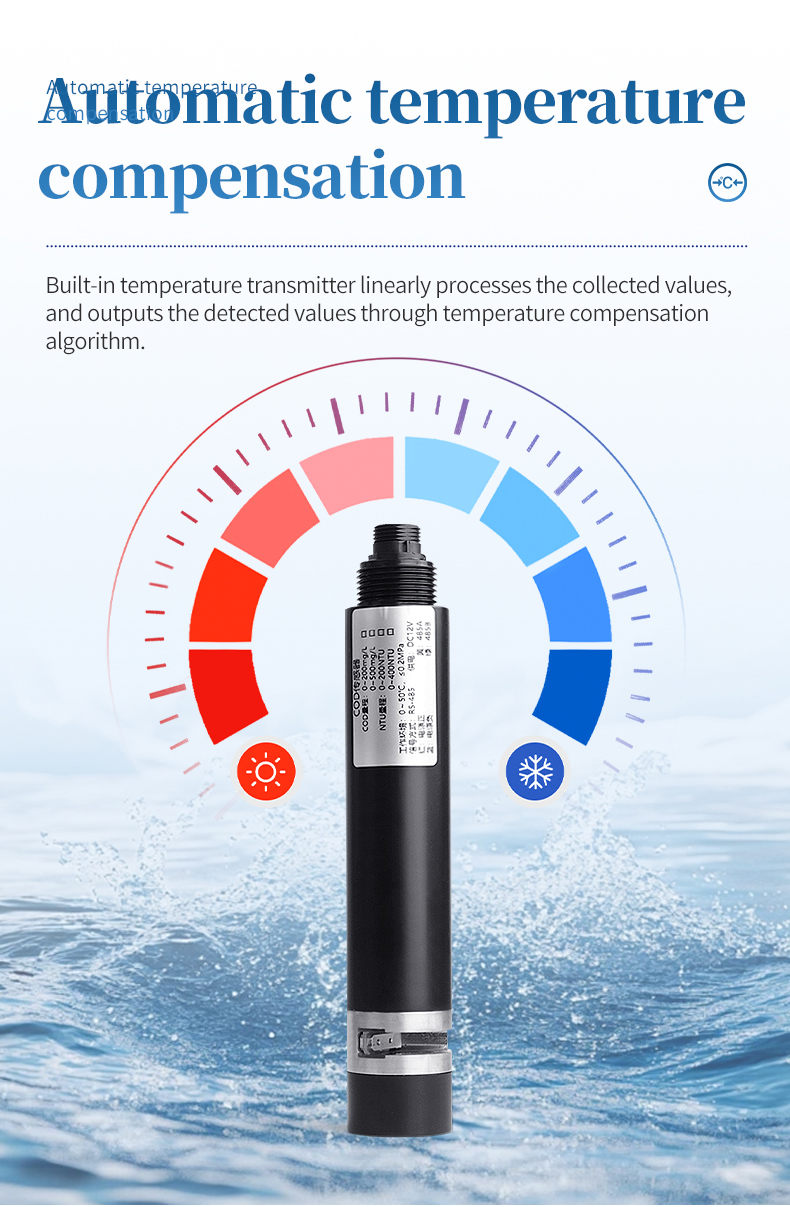

Temperature compensation: automatic temperature compensation

Output mode: RS-485 (Modbus/RTU), 4-20mA

Storage temperature: -5~+65 ℃

Working environment: 0-50 ℃,<0.3MPa

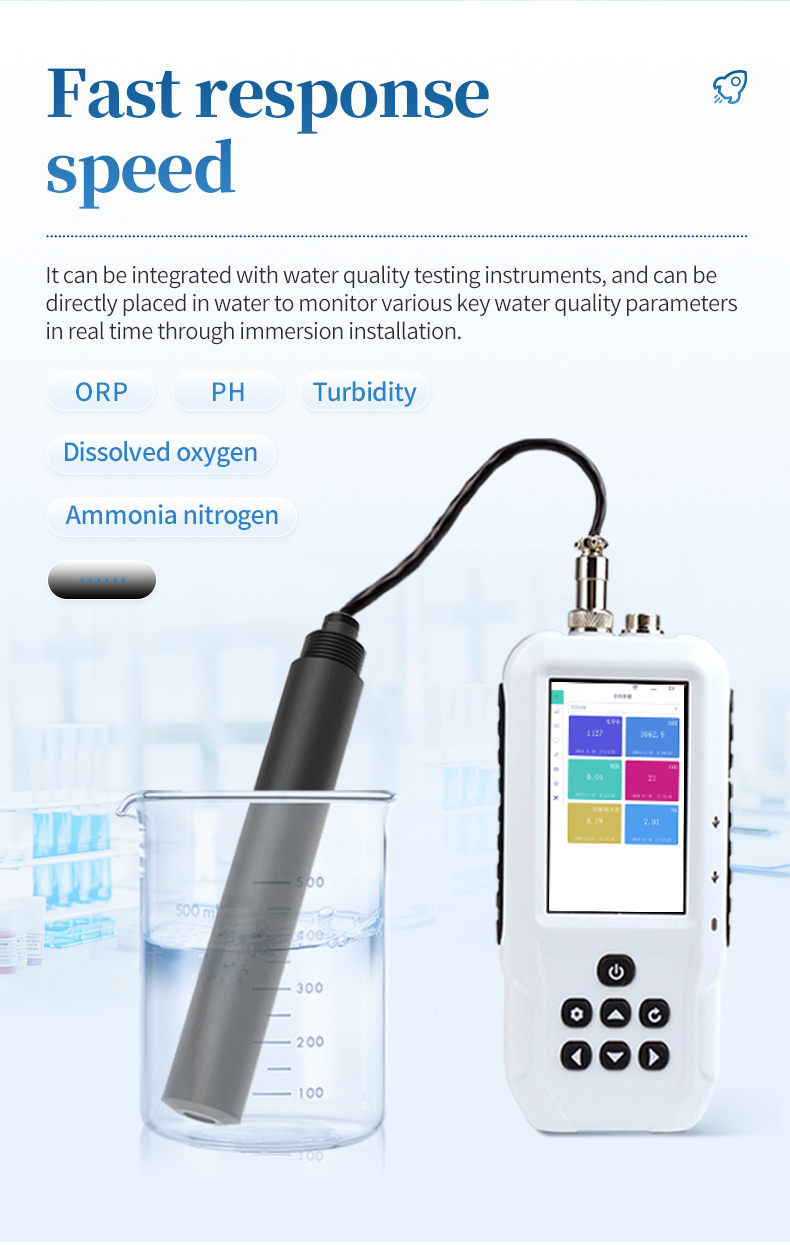

Installation method: Immersion installation, 3/4NPT installation thread

Cable length: 5m

Power consumption: 0.2W, 12V power supply

Power supply DC: 12V-24V

Protection level: IP68

Calibration method: two-point calibration

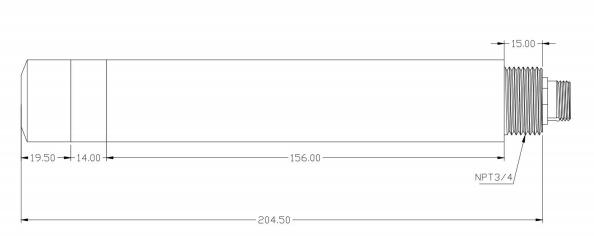

Size/Installation

1. Dimensional drawing

2. Wiring diagram

The cable is a 4-core shielded wire:

Red line - power cord

Blue wire - Ground wire (GND) Green wire -485B

Yellow line -485A

The cable color may vary slightly depending on the production batch, please refer to the cable silk screen printing for details.

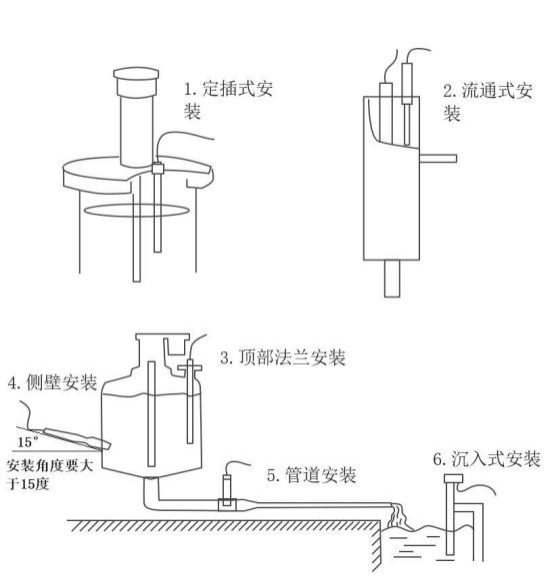

3. Installation

Before powering on, carefully check the wiring sequence to avoid unnecessary losses caused by wiring errors, and waterproof treatment should be carried out at the wiring points.

Maintenance and upkeep

1) Outer surface of sensor: Rinse the outer surface of the sensor with clean water. If there is still dirt residue, wipe it with a damp soft cloth. For stubborn dirt, add some household detergent to the water to clean it.

2) Fluorescent film head surface: If there is dirt on the surface of the fluorescent film head, please rinse with water or gently wipe with a soft cloth. When cleaning, pay attention to the force to avoid scratching the measurement area and affecting the measurement accuracy.

3) If the measurement value is too high or too low, the fluorescent film head should be cleaned and stirred during measurement to prevent the surface of the film head from being attached by foreign objects.

Sensor calibration

5.1 Zero point calibration

Add 95mL of water to 5g of sodium sulfite and stir evenly. Place the sensor into the solution and wait for 3 minutes for the value to stabilize. Then, perform zero point calibration according to the communication instructions.

5.2 Slope calibration

Place the sensor in air saturated water and wait for about 3 minutes for the values to stabilize before performing slope calibration. Follow the communication instructions to perform zero calibration.

5.3 Precautions

Avoid exposing the inner surface of the fluorescent film to sunlight or strong light. Do not touch the fluorescent film with your hands or sharp objects

Avoid attaching bubbles to the surface of the fluorescent film during use

Article address:http://www.hmwatertesting.cn/qtjc16/132.html

Related articles

-

Multi-Parameter Water Heavy Metal Detector: Spectrophotometry-Based Detection for 10+ Metals

2025-10-30 -

Portable Infrared Spectrophotometer for Oil Analysis: Rapid On-Site Detection of Water and Soil Oil Pollution

2025-09-19 -

What is a handheld water quality tester for for water quality measurement?

2025-07-23 -

BOD Analyzer | Effluent and Environmental Testing

2025-10-22 -

Multi parameter water quality analyzer: technological innovation for water safety guardians

2025-07-15 -

Product Knowledge Graph of Hengmei Intelligent Handheld Biotoxicity Analyzer

2025-11-04 -

Water Quality Detector | Portable Multi-Parameter Analyzer

2025-10-15 -

Handheld residual chlorine analyzer: a portable guardian of water quality safety

2025-07-15

+86 17853698681

+86 17853698681