Product Center

-

Multi Parameter Water Quality Analyzer

-

COD/BOD Analyzer

-

Determination of Ammonia Nitrogen

-

Determination of Total Phosphorus and Total Nitrogen

-

Biological Toxicity Testing

-

Disinfection Residue Determination

-

Online water quality monitoring instrument

Dissolved oxygen online analyzer PH online monitoring device Chloride ion online monitoring instrument Conductivity online monitoring device Turbidity online monitoring instrument Online water hardness monitoring instrument ORP online monitoring device Residual chlorine online monitoring device Total organic carbon monitoring equipment -

Other related tests

Water quality heavy metal detector Infrared oil analyzer Water quality nitrite analyzer Colorimeter Dissolved oxygen analyzer Turbidity detector Total OrganicCarbon Analyzer Chlorophyll detector in water Suspended solids analyzer Water quality total hardness/total alkalinity detector Surfactant detector Proportional water quality sampler Microbial detector in water Sulfide acidification blowing instrument Carbon dioxide detector in water Online water quality sensor Volatile Phenol Analyzer Phosphate Silicate Analyzer

Recommended articles

- Bromate Rapid Detector: Essential for Ensuring Packaged Drinking Water Safety

- Multi parameter water quality analyzer: technological innovation for water safety guardians

- COD Tester: Accurate and Efficient, Mastering the Pulse of Water Quality

- Handheld residual chlorine analyzer: a portable guardian of water quality safety

- What instrument is used to measure TOC?

- What are the advantages of water toxicity analyzer?

Current

location:HOME>PRODUCT>Other related tests>Online water quality sensor>Online Residual Chlorine Sensor

Current

location:HOME>PRODUCT>Other related tests>Online water quality sensor>Online Residual Chlorine Sensor

Product details

Application Environment Description

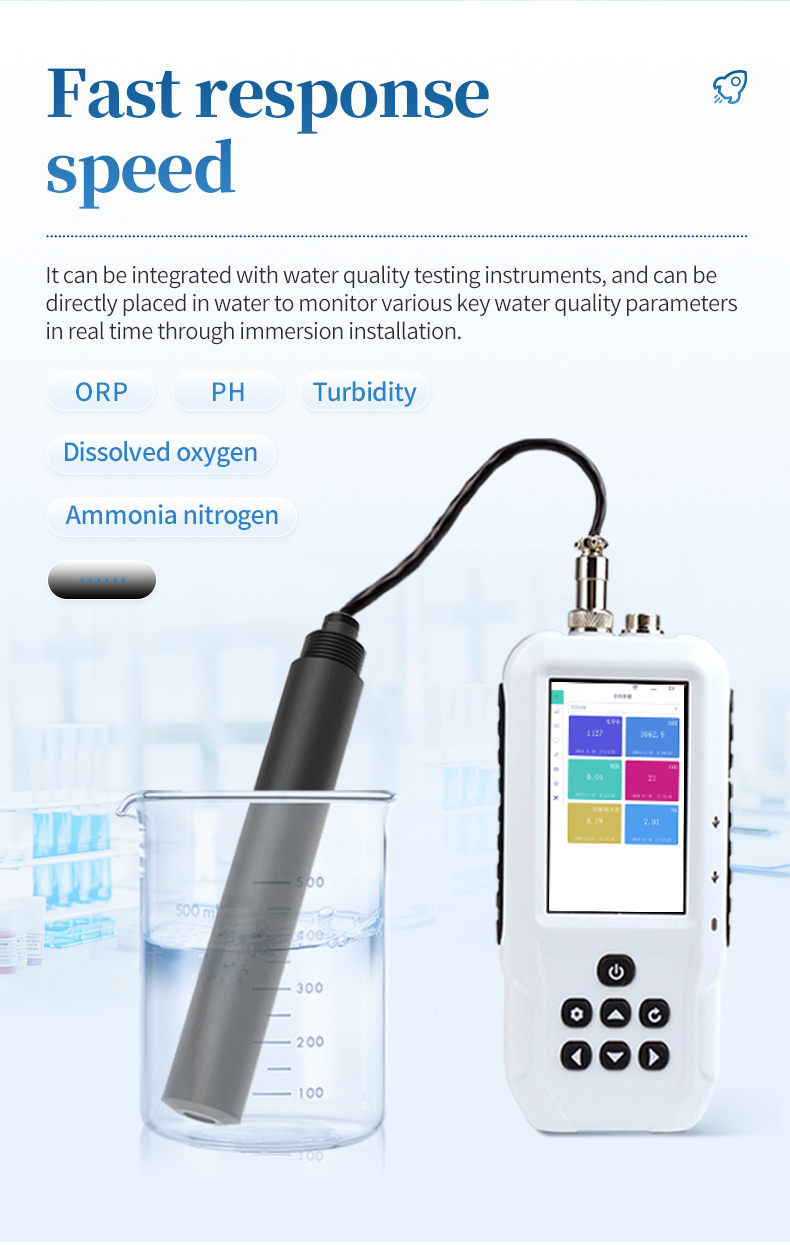

Used for continuous monitoring of residual chlorine content in water solutions in drinking water treatment plants, canning plants, drinking water distribution networks, swimming pools, cooling circulating water, water quality treatment projects, and other occasions.

Technical parameters

PH sensor:

Range and Resolution: 0~14 (PH), 0.01

Accuracy: ± 0.1PH; ± 0.3 ℃

Residual chlorine sensor:

Range and Resolution: 0~5.00 mg/L, 0.01

Accuracy: ± 5% of the reading; ±0.3℃

Communication method: RS485 (MODBUS-RTU)

Shell material: ABS

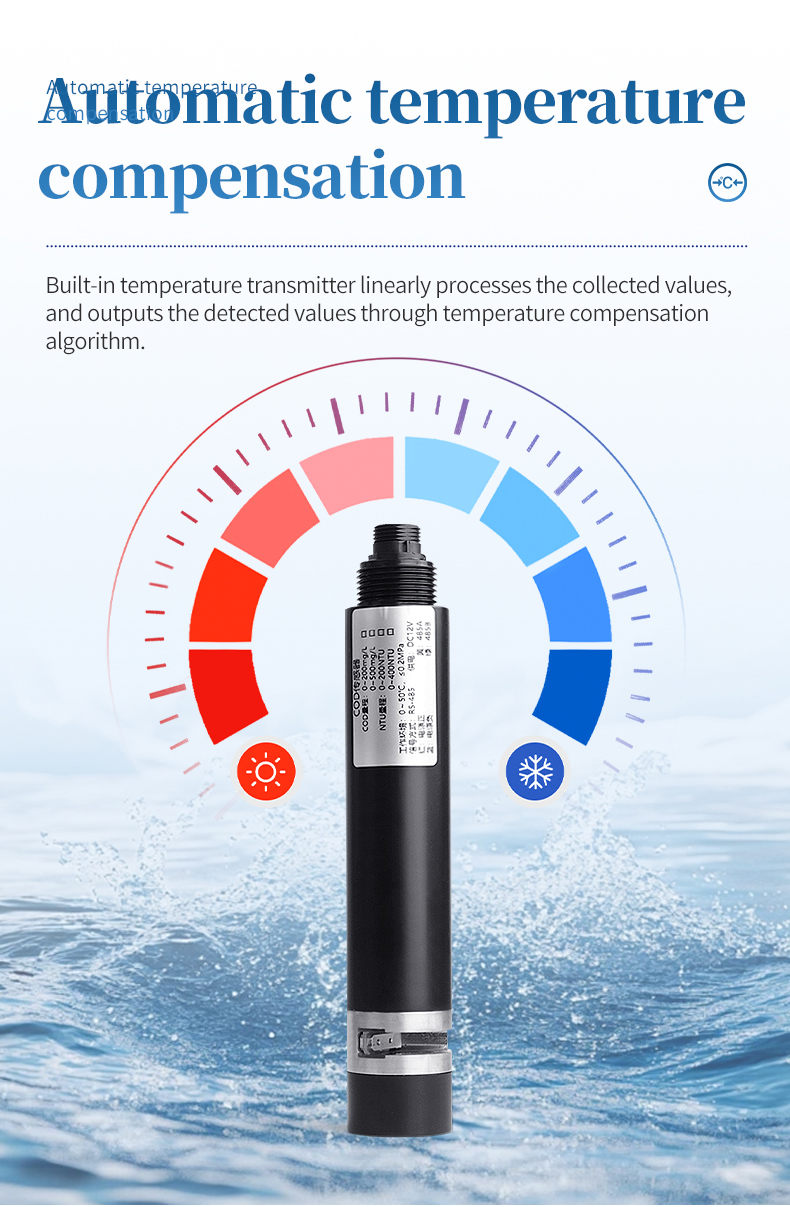

Temperature compensation: automatic temperature compensation

PH compensation: automatic PH compensation

Cable length: standard 5 meters

Supply voltage: 12-24VDC( 0.3W@12V )

Waterproof rating: IP68

Installation method: Flow pool installation, 3/4NPT

Electrical connection

1. Installation

Install the matching flow tank, with the sensor tightly attached to the flow tank. Ensure that the sensor measuring part is placed near the inlet of the flow tank, and avoid facing the outlet as much as possible to ensure a stable flow rate. It is recommended to control the flow rate at 30-60L/h to ensure the accuracy of the test.

2. Electrical connection

The cable is a 4-core twisted pair shielded wire, and the line sequence is defined as follows:

Red wire - power cord (12-24VDC) l

Black wire - Ground wire (GND)

Blue line -485A

Green line -485B

Note: The color of the cable may vary slightly depending on the production batch, and the specific color is subject to the cable silk screen printing.

Before powering on, carefully check the wiring sequence to avoid unnecessary losses caused by wiring errors.

Maintenance and upkeep

1. PH electrode

When used for the first time or left unused for a long time, the sensitive bulb and reference liquid should be immersed in a 3.3mol/L KCI solution for more than 2 hours. Before use, rinse and dry with deionized water (or distilled water) to prevent impurities from entering the tested liquid.

The wiring terminal should be kept clean and dry, and the sensor should be cleaned when not in use. It should be inserted into a protective sleeve containing 3.3mol/L KCI solution or into a container containing 3.3mol/L KCI solution.

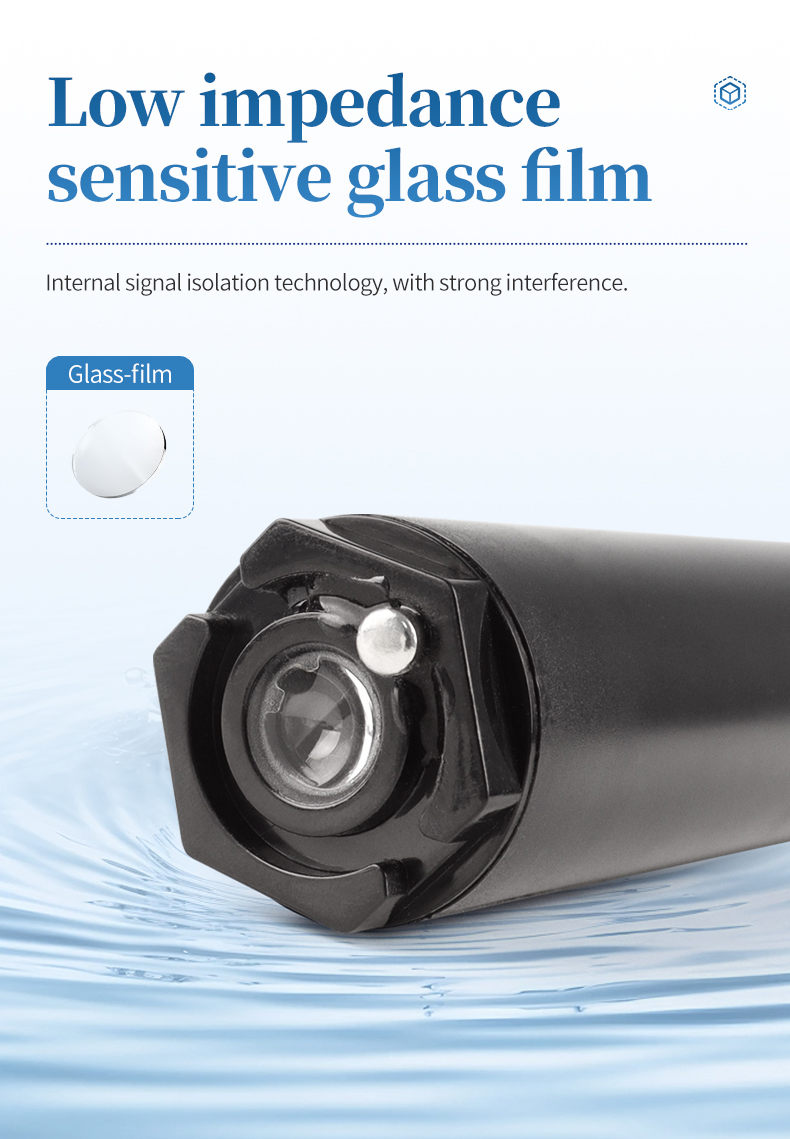

Check if the wiring terminals are dry. If there are stains, please wipe them with anhydrous alcohol and let them dry before continuing to use. Sensors should avoid prolonged immersion in deionized water, protein solutions, strong acid and alkali solutions, and acidic fluoride solutions, and prevent contact with organic silicone oils and fats. Sensors that have been used for a long time may have their glass film become semi transparent or have sediment attached. In this case, dilute hydrochloric acid can be used to wash and rinse with water.

When the sensor has been used for a long time and measurement errors occur, it can be calibrated and corrected by cooperating with the instrument. If the above methods of maintenance and upkeep still cannot calibrate and measure the sensor, it indicates that the sensor has failed and should be replaced.

2. Residual chlorine electrode

New electrodes and electrodes that have been placed for a long time need to be activated before use. The sensor should be left to stand in tap water for 24 hours. If the returned value is inaccurate, the following operations need to be performed:

Perform zero and slope calibration on the sensor

Return to factory inspection

Article address:http://www.hmwatertesting.cn/qtjc16/130.html

- Previous: Online pH Sensor for Water Quality

- Next: Water Quality Conductivity Sensor

Related articles

-

Hengmei Intelligent Portable Biotoxicity Tester Product Knowledge Graph White Paper

2025-12-18 -

What are the water quality tester test items?

2025-07-23 -

What are the advantages of water toxicity analyzer?

2025-07-23 -

Bromate Rapid Detector: Essential for Ensuring Packaged Drinking Water Safety

2025-09-30 -

Water Quality 4-Nitrogen Analyzer | Ammonia, Nitrate, Nitrite, Total N

2025-10-22 -

Infrared spectrophotometer: the "spectral guardian" guarding green mountains and clear waters

2025-07-15 -

BOD Analyzer | Effluent and Environmental Testing

2025-10-22 -

What is the best water tester for drinking water?

2025-07-23

+86 17853698681

+86 17853698681